Safety Shoes for Craftsmanship and Plant Engineering

(81 Results)

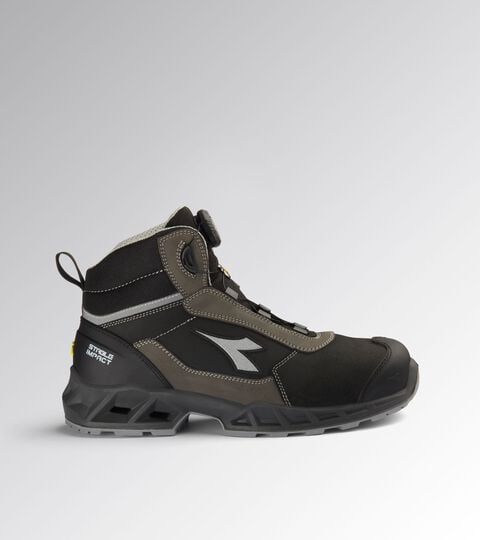

SPEEDY RACE MID S3S FO SR SC MET FREE - High safety shoe - Diadora Utility x Ducati Corse

Safety Shoes for Installations

The best safety shoes for installation work are versatile, durable, and comfortable.

Working in installation involves a variety of tasks, situations, and environments with diverse characteristics. It can take place indoors in more or less controlled settings, but also outdoors on construction sites that pose puncture risks, at heights, or in cramped spaces that require uncomfortable positions. Depending on the sector, an installer might work with delicate electronic components, in damp environments, or in the presence of flammable materials.

To meet the protection and safety needs of electricians, plumbers, electromechanical installers, and anyone involved in the design, installation, and maintenance of industrial or construction systems, the best safety shoes for installers must be versatile, robust, and comfortable.

Clearly, choosing the most suitable protective footwear for your specific use requires considering all the specifics of your work activity. However, in our guide, we will explore some general features that make an excellent safety shoe for installation both safe and high-performing.

1. Robust and Puncture-Resistant

The primary function of safety footwear is protection. Safety shoes for installers are designed to protect against punctures when working in environments that pose this risk, such as construction sites during system installation, or during maintenance in areas where you might step on nails, broken glass, or other hazards. The safety category to consider might be S1P (shoes equipped with a puncture-resistant plate) or S3 for situations that also require a water-repellent upper.

2. Well-Cushioned

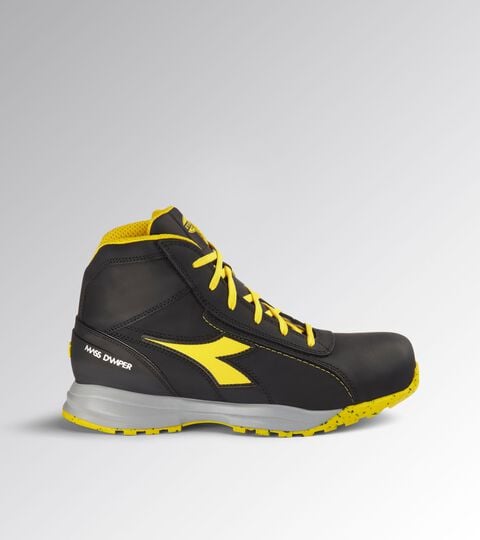

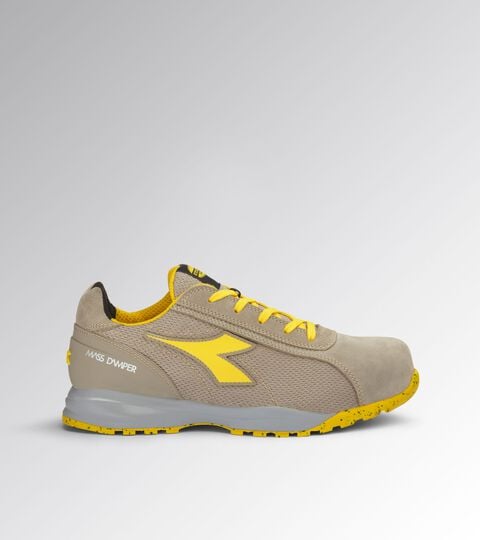

When you wear the same pair of shoes for many hours and almost every day, wearing well-cushioned safety shoes that reduce muscle fatigue is not just a matter of comfort but also of safety. Choose a model that optimizes cushioning, such as Diadora Utility shoes with Mass Damper technology: these are highly versatile work shoes, suitable for both dynamic activities and the more static phases of installation work, where good support and stability become indispensable.

3. Wear and Abrasion Resistant

To achieve good durability over time despite intense use, look for shoes that are resistant to wear and abrasion not only in the sole but also in the materials used for the upper. New-generation technical fabrics are resistant to tears, flexing, and abrasion while remaining lightweight and breathable: if your activity requires high wear and abrasion resistance, opt for models that use technologies like Matryx 2.0, a technical fabric made of Kevlar® and high-tenacity polyamide developed in collaboration with Diadora by Chamatex®, a company specialized in high-performance technical fabrics.

4. Water-Repellent

If you work with plumbing systems or in damp environments exposed to the elements, make sure you finish the day with dry feet and choose safety shoes with a water-repellent upper: in full-grain leather, nubuck, or suede, or in lighter technical fabrics, but always water-repellent.

5. Slip-Resistant

If your job takes you onto slippery or steep surfaces, a slip-resistant sole might not be enough, which is a basic requirement for any safety shoe. If your job exposes you to particular slipping risks, opt for safety shoes with the additional slip-resistance requirement: they are marked with the codes SRA, SRB, or SRC, and we discuss them more extensively in this article.

6. ESD Shoes

If you work with equipment and electronic components sensitive to electrostatic discharge, such as microchips or electronic boards, your activity might require the use of ESD safety shoes, which discharge static electricity from the body to the ground more efficiently and consistently than antistatic shoes. To learn more about ESD shoes, we recommend reading the article dedicated to them.