Certified Safety Shoes

(144 Results)

Classification of Safety Footwear

What is a legally compliant safety shoe?

What does the CE safety footwear regulation entail?

What are the characteristics of S1P safety footwear?

Answers to your questions about the four European standards, the classification of work shoes, and their minimum safety features.

What is a safety shoe?

A safety shoe, also known as "protective footwear," is a special type of shoe designed to protect the foot during work activities. The use of these shoes is mandated by our legislation for many categories of workers, as described in the Consolidated Law on Health and Safety at Work (Legislative Decree 81/2008).

To ensure protection in various working conditions and environments (from road construction sites to foundries, and even bars and restaurants), safety footwear must meet minimum safety requirements common to all types of shoes. Depending on the model and the intended user, they may also have specific optional features—such as electrical insulation, resistance to heat or cold, waterproofing, and more.

The minimum requirements for safety shoes and the different classifications based on their characteristics were established by a series of European standards introduced in 2012. According to Italian law, shoes can only be considered safety footwear if they meet these safety standards and bear the European conformity mark "CE," followed by the reference standard number.

These are codes, acronyms, and numbers that you must ensure are present on the technical sheet and label of each legally compliant and reliable safety shoe:

- The European conformity mark (CE)

- The number of the European reference standard, for example, EN ISO 20345

- The classification code of the shoes, identifying the protection class with its mandatory and any additional requirements, for example, S1P, S3, P4, etc.

The CE Regulation on Safety Footwear

The four European standards concerning work shoes examine three different types of footwear, classify them based on their level of protection, and indicate how to test them for certification.

The European standard EN ISO 201344 defines the general requirements and the methodology for testing the protection level of footwear. The subsequent standards, EN ISO 201345, EN ISO 201346, and EN ISO 201347, detail the mandatory and additional characteristics of the three classes of work footwear:

- EN ISO 201345: This standard classifies safety shoes with a toe cap resistant to 200 Joules, identified by the letter "S."

- EN ISO 201346: Describes the specifications of protective footwear with a toe cap resistant to 100 Joules, identified by the letter "P."

- EN ISO 201347: Describes the specifications of professional footwear without a protective toe cap, identified by the letter "O" (from "occupational").

In addition to the minimum requirements, each class of footwear can have supplementary safety features, coded with additional numbers or letters of identification (see tables).

For example, the most sold safety shoes are the S1P safety shoes, indicated by the acronym:

- Safety shoes with the minimum requirements, i.e., equipped with a 200 Joule toe cap and an upper made of leather, split leather, or synthetic fabric of the minimum height required by the standard (S);

- Antistatic, with an anti-slip sole resistant to hydrocarbons, and a shock absorber in the heel area (S1);

- Equipped with an anti-perforation midsole as an additional protection (P).

Minimum Requirements and Classification of Safety Shoes (S)

When choosing safety footwear, it is crucial to know the required protection category based on the workplace and type of job, usually belonging to the group of safety shoes (S) compliant with ISO 201345.

Safety shoes are further classified into different categories depending on their level of protection and specific characteristics.

Safety Category SB

Defines the basic requirements of safety shoes: reinforced toe cap resistant to 200 Joules; anti-slip sole resistant to hydrocarbons and oils; upper made of leather, split leather, or synthetic fabric of minimum height.

Safety Category S1

In addition to all the characteristics of SB shoes, S1 safety shoes have an antistatic sole and a shock-absorbing heel.

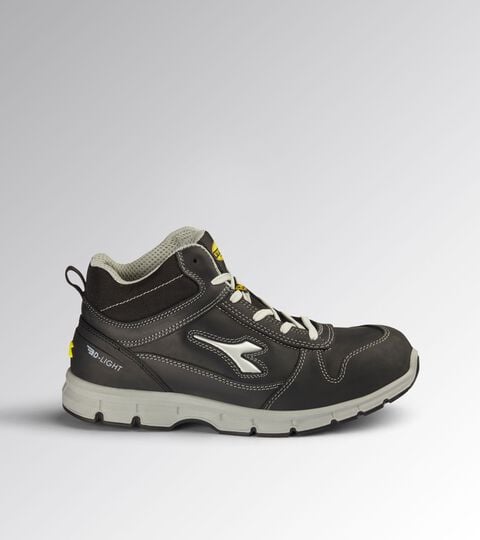

Safety Category S1P

S1P safety shoes are the most common safety footwear. They have the same features as S1 shoes, plus an anti-perforation midsole.

Safety Category S2

S2 category shoes have all the features of SB and S1 shoes, plus a waterproof upper resistant to contact and immersion in water for up to 60 minutes. They do not have an anti-perforation midsole.

Safety Category S3

S3 safety shoes have a water-repellent upper and all the other features of the S2 category, plus an anti-perforation midsole. Like the S1P, these combined features make the S3 safety shoe a complete and versatile product, suitable for various types of work—for example, for those working outdoors in adverse weather conditions, thanks to the water-resistant upper.

Safety Category S4

While all previous categories refer to footwear with an upper made of leather or synthetic material (microfiber or similar), the S4 category pertains to rubber or PVC boots, completely waterproof with no time limits, particularly suitable for those working in water. The features are similar to those of the S1 category.

Safety Category S5

S5 shoes and boots are also waterproof rubber or PVC footwear, with the same features as S4 shoes, plus an anti-perforation sole.